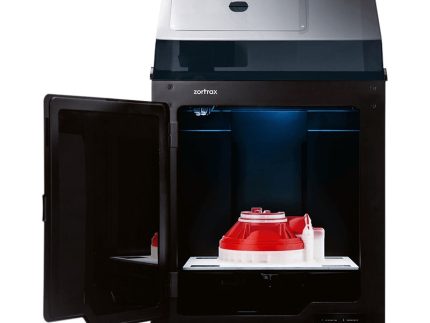

Zortrax Z-ABS Filament Dedicated for Zortrax M200 Zortrax M200 Plus

Zortrax Z-ABS Filament Dedicated for Zortrax M200 Zortrax M200 Plus

The mat surface of Z-ABS is easy to post-process. The material can be treated chemically or mechanically. You can use acetone to merge bigger parts 3D printed separately. The cost-effectiveness of Z-ABS goes even further. You can reuse rafts and peeled off support structures to prepare ABS juice. Simply mix them with acetone and apply onto the build platform to increase adhesion of the first 3D printed layer.

* Please note, there are two types of Z-ABS material that are included in the range of Zortrax materials: Z-ABS and Z-ABS v2. Both have the same properties, however, as their printing settings differ – two profiles, Z-ABS and Z-ABS v2 are available in Z-SUITE. The spools of both Z-ABS types are tabbed accordingly, and we recommend making sure which one you’re using by checking the material sticker and choose the right printing profile. In case you’re printing a .zcode or .zcodex previously sliced for Z-ABS, slicing them again with the Z-ABS v2 profile is necessary for printing with the v2 material type. Please see more information on the Zortrax Support website.

| Dedicated for | Container | Weight | Diameter |

|---|---|---|---|

| Zortrax M200 | spool | 800 g. ±5% | 1,75 mm |

| Zortrax M200 Plus |

| Key Properties | Metric | Imperial | Test Method |

|---|---|---|---|

| Izod Impact, Notched | 8.93 kJ/m2 | 4.25 ft-lb/in2 | ISO 180:2004 |

| Elongation at Break | 11.08% | 11.08% | ISO 527:1998 |

| Glass Transition Temperature | 107.89oC | 226oF | ISO 11357-3:2014 |

Applications

- Prototypes

- Concept models

- Low-cost drafting

- Casings

- Figurines

- Gaming and toys

- Gadgets and decorative accessories

- Display models

- DIY projects

- Educational Aids

Basic material

Low-cost 3D printing

Easy post-processing

- Download Z-ABS Safety Data Sheet

- Download Z-ABS Technical Data Sheet

Specification

| Dedicated for | Container | Weight | Diameter |

|---|---|---|---|

| Zortrax M200 | spool | 800 g. ±5% | 1,75 mm |

| Zortrax M200 Plus |

| Key Properties | Metric | Imperial | Test Method |

|---|---|---|---|

| Izod Impact, Notched | 8.93 kJ/m2 | 4.25 ft-lb/in2 | ISO 180:2004 |

| Elongation at Break | 11.08% | 11.08% | ISO 527:1998 |

| Glass Transition Temperature | 107.89oC | 226oF | ISO 11357-3:2014 |